May 2015, updated September 2015.

The North Platinum 190-250 cm boom.

A review - wrapped in a

general boom discussion.

In the late autumn of

2014 I got a brand new North Platinum 190-250 cm boom for use with my big

slalom gear. Due to

my fragile body sustaining some smaller injuries, the boom was not wetted

until early in 2015, but although I haven't used the boom that much, a

clear

image of its function and performance

has certainly been formed.

So far, the boom

has solely been used with a North Warp F2013 9.2 on a RRD X-Fire 129 and

a Fanatic Falcon 152.

A North Warp F2013 9.2 sail with the North Platinum 190-250 cm boom.

Click the picture to enlarge.

There'll be plenty of

words below, so I'll not tire you with a description of the key features

of the boom. Instead I can refer to this (coloured) description from the

North homepage:

http://www.north-windsurf.com/eng/nodes/display/product/platinum-series-1

and this presentation of the general boom technology of

the company:

http://www.north-windsurf.com/eng/nodes/display/pages/boom-technology.

The review.

In this review I'll use my experience with booms from other brands as a reference. That is, the Platinum boom will be "measured" by comparing it to other solutions, both good and flawed, that I've come across over the years.

With a personal, but

rather vague, order of priority, the most important qualities for booms

this size are listed below. They

are as follows:

1.

The main parts of booms this size must be manufactured from carbon fiber.

Generally,

carbon booms are stronger, more durable and stiffer than aluminum booms.

And furthermore,

if

a carbon boom weakens,

you'll very often have a

chance of noticing

unhealthy noises and locating

cracks before any fatality, whereas aluminum booms

have an unfortunate tendency to explode without warning. Contrary to carbon, aluminum develops

fragility from continuously bending,

and broken aluminum isn't repairable. However, if you

locate

some cracks on a carbon boom, it's

sometimes

possible to file/sand down some of the bad material and add

new layers of carbon or glass fiber weave. And of course, you can also

strengthen sound areas of a carbon boom as

preventive measures.

The remains of an exploded Neil Pryde X6 boom. The

aluminum made X6 boom has an extremely bad reputation -

and a well deserved one!

Click the picture to enlarge.

The front piece of a Fiberspar carbon boom has cracked. Judging from

where the cracks are located, Repairing the front is actualy feasible.

- although perhaps not advisable.

Click the picture to enlarge.

How does the Platinum

boom meet this demand?

Well, my new

Platinum 190-250 cm boom is

indeed made from carbon fiber - but more than that: Carbon is not carbon

- in the sense that carbon fiber laminated with a lot of resins is not

nearly as strong as carbon fiber laminated with just enough resins. A

(say) 2 millimeters carbon laminate consisting of relatively few layers

of fiber, bonded together with lots of resins, is not nearly as strong

as lots of layers of fiber, bonded together with very little resins.

North claims that the

Platinum boom is manufactured from pre-wetted (prepreg) carbon weave, so

apparently the carbon weave contains only a minimum of resins. Simply

from feel I can say that the exposed carbon on the Platinum boom is a

lot more scratch resistant than any carbon boom I've owned. I see this

as a clear sign of a very tough boom, probably the toughest boom in my

arsenal. And just an interesting detail: Some of my carbon booms have

signs of casting, indicating that two halves of tubes are glued

together, but not precisely aligned. The Platinum boom has no such signs

...

2.

The boom front must

be integrated with the tubes (a monocoque construction).

Among the carbon

booms, to my knowledge only the Nautix carbon booms still have a "loose"

front section/head that's connected to the tubes with glue (epoxy?). The

old Fiberspar carbon booms also had a separate boom front that was glued to the tubes.

Although seemingly

old fashioned, I'll always prefer this system

if there's any risk that

the boom front of a monocoque construction will crack. For instance,

if

the front cracked on a Fiberspar boom you could always buy another front

and glue the boom together - while the frequently cracked fronts on

(only earlier?) Neil Pryde X9 booms imply trashing the entire boom.

A Fiberspar carbon boom (with Maui

Sails head) reinforced with glass

fiber weave for preventive reasons.

Click the picture to enlarge.

A Neil Pryde X9 boom front shows

some ominous cracks. Repairable?

Look at the next picture.

Click the picture to enlarge.

The head das been removed from

the NP X9 boom front. The location

and the seriousness of the cracks

tell that there's no salvation for

this boom.

Click the picture to enlarge.

A couple of old-type Nautix

integrated boom fronts/heads.

The front/head to the right is meant

to be laminated into Nautix carbon

tubes. Compared to a fragile

monocoque construction, I'll

always prefer this system.

Click the picture to enlarge.

How does the Platinum

boom meet this demand?

The Platinum boom is

a monocoque construction, where you'll have to hope for durability of

the boom front as there's no possibility for renewal. However, to my

knowledge boom front cracking problems isn't widespread these days, and

with the very strong appearance of the Platinum boom I foresee no

problems in this respect.

3.

The boom head clamp

mechanism must grab the mast with NO tendency to slide down.

I've very seldom possessed booms that didn't slide down the mast with 7.8'ish sails and bigger. Frankly, I don't understand why this issue isn't discussed more among windsurfers, and I suspect that many sailors simply are not aware, and don't give it a thought, why the control of the sail gets better and why the speed and liveliness of the board get worse during a session. In short: Booms slide down without many sailors giving it a thought.

One of the very few

exceptions from the enervating sliding-down problem is the Nautix booms

(with a "loose" front piece, not a monocoque construction). And from the

other end of the spectrum my Maui Sails booms have always been sliding

down. And

mentioning

the Maui Sails booms - attempting to tightening the head, the only

consequence is to crack it. I've used fortunes on

renewing

cracked MS

booms heads, and I'm very surprised that the MS people think they can

get away with blaming the costumers for this defect: There's simply

no

way to avoid boom head sliding

and at the same

time avoiding cracks for the Maui Sails heads. You'll have to choose - a

cracked boom head or a sliding

down boom head.

The classic Maui Sails boom head problem: You'll have to choose

between boom slip or a cracked head. Here are e few heads from

my personal collection.

Click the picture to enlarge.

In desperation over the waste of money for replacement for the

cracked Maui Sails heads I've tried to come up with alternatives

for trashing them. Please note that there're no "overlapping"

heads in the two pictures.

The final solution was to replace the heads with the very rugged

Streamlined boom heads that fit perfectly to the Maui Sails

boom fronts.

Click the picture to enlarge.

The boom sliding problem is monstrous irritating, and I've made it to a procedure to put on an anti-skid coating in the boom area of all my masts as soon as they arrive from the shop. This helps, but for some of my booms (Maui Sails, Streamlined, Neil Pryde and others) it only reduces the problem.

A couple of ways to increase the friction between boom and mast. In

both ways the boom areas of the masts are wetted with a thin layer

of epoxy. The areas are then either covered with a rough masked

nylon cloth (the masts to the left and to the right), and the cloth

are removed when the epoxy is hardened.

The mast in the middle is treated the same way as when putting

an anti-skid layer on your boards (epoxy sprinkled with sugar that's

washed away, when the epoxy is hardened).

More on the subject here:

http://peterman.dk/windsurf-anti-boom-slip01-1200.htm

Click the picture to enlarge.

An Aeron boom head equipped with pieces of rubber/soft plastic,

taken from an old Nautix boom head. I'm astonished why some

brands seem to think that hard plastic against a smooth mast can

create sufficient friction to avoid boom sliding.

Click the picture to enlarge.

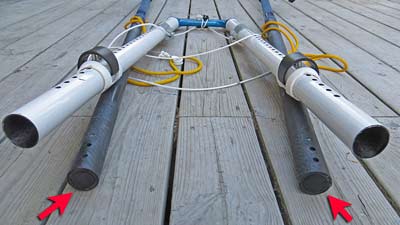

Update September 2015.

The simplest mean's

often the best: A string threaded through a couple of holes (made with a

soldering iron) is tied to the boom front. In the picture the

anti-boom-slipping line is used with a North Warp 8.6, rigged on a

Platinum 490 with a Nautix boom with a Streamlined boom head (older

type). Until this solution the Streamlined boom head ALWAYS slipped a

couple of cm every 10 minutes - especially in bumpy conditions.

The "system" is

quick made (a couple of minutes) and very, very effective. And so far

I've noticed none negative effects on the sail whatsoever. A no-nonsense

solution that works!

The picture's from

the test session. No need to fasten the boom head in kind of double

string. A single string will do.

Click the picture to enlarge.

How does the Platinum

boom meet this demand?

Perhaps you think

that having a boom that doesn't slide down your mast is a banality and

truism. In my opinion it's not.

I've used the

Platinum boom with two original heads (iFRONT 1.0 in the stiffest setup

and iFront 2.0 in the "stiffness III" version).

Neither of them

showed the slightest tendency to slide down

the mast.

It's

my

experience that

such

non-slipping quality isn't that common.

Update February 2016.

Trimming boom height on the water.

As said, the Platinum iFront 2.0 clamps very securely onto the mast. It

does so by almost sucking the mast with the friction pad - in fact the

friction pad gets in contact with the mast way before the clamp is fully

closed.

In a review of the

Platinum Aero 190-250 boom, Andreas Wale

(who is otherwise very satisfied with the boom) from

Sweden has pointed out that the early contact between the

friction pad and mast can cause a problem if you're the kind of guy that

frequently adjusts the boom height on the water: To release the iFront

2.0 sufficient from the mast to allow boom height adjustments, you'll

have to open the lever fully, and by doing so you risk (or: You're damn

sure) that the tightening string gets loose from the cuff.

It would be unfair

to criticize that the Platinum boom head ties firmly to the mast very

early when operating the lever. In fact, this is probably the cause why

it isn't member of the annoying "sliding down the mast syndrome family"

- a family way too big!

However, if you're

the kind of sailor that use to trim the boom height on the water, it

would be nice if you could open the lever without the string falling off

the cuff, and thus avoid the fiddling issue to replace the string

before clamping the boom in a new position.

Without going into

details I think it would be pretty easy for the gifted North people to

help the guys with the habit of trimming the boom height on the water -

for instance by "locking" the string better to the cuff. By doing so

North would satisfy sailors that focuses on easy boom height trimming on

the water (like Andreas)

and sailors that focuses on boom heads that

don't slide down the mast (like me).

The iFront 2.0 clamp has to be

almost fully opened to allow the

boom height to be adjusted.

Click the picture to enlarge.

When opening the clamp fully, the

string almost certainly falls off the

cuff - unless you keep the string

tight by simultaniously pullling

back the cuff (as done here).

Click the picture to enlarge.

4. The boom head clamp mechanism must not crush the mast

.

The Platinum 190-250

cm boom was delivered with a iFRONT 1.0 boom head. The head can be

stiffened up by moving around a couple of screws, and as the boom was

intended for use with a race sail, it was

stiffened max. For curiosity - and for this review - I ordered

the new

2015 iFront 2.0 boom head ("Stiffness III" version) and have been

using this head the last couple of sessions.

No need to go into

technical details, but from the view of the user the main difference

between the heads seems to be that the new head accepts different mast

diameters somewhat better than the iFront 1.0. As said, also the iFront

1.0 sits firmly on the mast, but it seems that it point loads thicker

masts more than the new iFront 2.0. The iFront 2.0 simply seems to be

more careful to larger diameter masts. As I (for reasons described here:

http://peterman.dk/windsurf-north-warp-1000.html) am tied to use the

older large diameter pre-drop shape Platinum 490 cm masts for my Warp

9.2, I've decided to use the iFront 2.0 boom head.

The Platinum 190-250 cm boom

with the iFront 1.0, it was delivered

with - placed behind the new 2015

iFront 2.0 boom head.

Click the picture to enlarge.

The ability of the iFront 1.0 boom

head to fit tight to an older North

Platinum 490 cm mast and the

new Platinum 490 cm mast.

Click the picture to enlarge.

The ability of the iFront 2.0 boom

head to fit tight to an older North

Platinum 490 cm mast and the

new Platinum 490 cm mast

Click the picture to enlarge.

It always comes as a surprise just

how time consuming it is to fit a

new boom head to a boom front.

Fitting a iFront 2.0 boom head to

a Platinum boom front certainly

isn't an exception - indicated by

the tools used.

Click the picture to enlarge.

How does the Platinum

boom meet this demand?

I don't foresee any

problems with durability of my masts

when used with the iFront 2.0 boom

head.

5. No water in the boom, please

!

Water in the boom is

annoying - and unfortunately

pretty

common. Objectively I'm not sure that it means a lot to have a boom that drinks some water. But mentally

it's very de-motivating to listen to the gurgling noise of water from

the boom and see the water pouring out of the tail when coming ashore.

It's not a problem to

cork the tail end of a boom to avoid this kind of water entrance.

However, it's a real problem to fix the most common source

of the water

entrance problem - the holes (hollow depressions) for the adjustment

pins. Holes that are intended

not to give access for water

to

the interior

of the tail end - but holes that due to lousy manufacturing quality very

often suck water.

As

said, it's

a very

elaborate work to try to repair the leakage in the pin holes, and often

it's much better to simply to drill some holes for draining water out in

back of the tail end or underneath of the tail end. This way, of course,

water can get into the boom, but it also gets out

again as soon as you lift

the boom from the water.

The gurgling noise from this almost new Neil Pryde X9 tail end indicated

water entrance. A pressure test revealed that 6 pin holes leaked (here

encircled with a white marker). Result: The water gets in easily - but is

almost impossible to get out.

Click the picture to enlarge.

How does the Platinum

boom meet this demand?

The North people has

taken the consequence of the trapped-water problem and have given water

free access to get into the tail end of the Platinum boom - and

more important: Free

access to get out as soon as it gets out of the water. This is a

no-nonsense solution, that furthermore allows the tail

end

to be very light (no need

to laminate extra

material inside the tail

end tubes

to place the pin holes in)

and allows the

tail end to fit outside the tubes for stiffness reasons. Simple and

elegant!

6.

The width of the boom

shall accept the profile depth of the sail - but only just.

I think many of us

have experimented with shortening booms - for several reasons:

Substituting an older race sail with a new one in the same size often

imply an 10-20cm shorter boom length because of the trend with cut outs

at the clew. Another source for boom shortening experiments is the large

stock of very long booms - up to 310 cm on length - that some shops sell

very cheaply because of the diminishing market for very big formula

sails;

carbon

booms of high quality that only have a chance for being used and

sold if shortened.

Anyway, from the boom

shortening business I have several times

ended up using a boom

that felt too

wide. The trim simply were wrong, and the manoeuvres felt awkward. My

son and I have 7 booms for sails in the 6.3 - 9.2 sizes, and the width

of the booms (inside the tubes, between the harness lines) vary from 50

- 59 cm. Personally, for a 9.0 - 9.5 sail on a large slalom board, I

feel that a boom width between 50 cm to 55 cm is best. A little

dependent of the tail width of the boom, I prefer that the sail touches

the boom tubes

slightly from the outhaul

clam cleats backwards when releasing

the outhaul for a downwind run.

How does the Platinum

boom meet this demand?

The Platinum 190-250

cm boom has a width of 50,5 cm between the harness lines (for a Warp

9.2). That's relatively narrow, but for me that's spot on. Also because

of the outline of the boom (see later).

7.

The shape of the boom

must be classic with no "new-school" bend curves or the like of the

tubes.

For larger booms I don't fancy "new school" shaped booms. Bigger sails have the draft a long way back from the mast, so I find no reason to drastically change the proven boom shape forward towards the boom head. With smaller sails, where the harness lines and your hands are placed closer to the mast, perhaps it's another story.

How does the Platinum

boom meet this demand?

The Platinum 190-250

cm boom has a reasonable classic shape. The tail is moderately wide, and

the shape from the front to the wide point is certainly not what can be

called

a

"new-school" shape.

However, the shape of this section is kind of segmented in

a couple of fairly

"straight" curves, that allow the front hand

to be almost in line with the back hand. This segmented curve is subtle,

I must admit, but I think it's there.

Perhaps that's the reason why

the boom simply

feels

nice to have in your hands.

The Platinum 190-250 cm boom is placed upon a Maui Sails boom.

The shapes of the tubes between the harness lines end the boom

head differ a little, giving the Platinum boom perhaps a little

more natural feel for your front hand.

Click the picture to enlarge.

8. The boom must be stiff, also fully extended

.

The stiffness issue

isn't as urgent as earlier. The need for very long (formula) booms kind

of standardized

the contemporary

appearance

of bigger carbon booms, so that in the harness line

area the diameter is "grab-friendly", while the

diameter towards the

front and

tail is oversized. This boom style has proliferated

down the slalom sizes, although the need for oversized tails isn't that

urgent here. Frankly, sailing with 7.0-7.8 and smaller slalom sails I

prefer to have an ordinary old-style carbon boom in my hands - like the

good old Fiberspar booms without the heavy oversized tails, that often

feel

a bit

un-balanced.

However, for sailing

with slalom sails bigger than 7.8 meter, the stiffness of the oversized

tails is a benefit. Before receiving the Platinum 190-250 cm boom I

sailed my Warp 9.2 with an old Fiberspar boom (with Streamlined head)

without oversized tail, and it felt very light and balanced in the

hands, but also somewhat wobbling.

How does the Platinum

boom meet this demand?

I've done no

"scientific" test of the stiffness of my Platinum boom compared to other

of my carbon booms. However, the carbon quality of the boom, the unique

end piece, the large overlap between tubes and end piece, the extension

mechanism and (most important) the feel of the boom on the water give

reason to say, that this is a very, very stiff boom. I'm in no doubt

that it's the stiffest boom I've had.

9. The boom must be prepared for outhaul trim - and a little about the outhaul lines/pulleys in the clew

grommet hooking

.

Using

a boom for

slalom sails, outhaul trim is a must. Personally I have outhaul trim on

all of my booms (for sails down to 5.0 meter). An outhaul trim requires

pulleys in the tail end, and I think that almost all serious boom brands

have this feature these days. If your (older) boom doesn't have the

required (3) pulleys in the tail end, you'll have to make it yourself,

and in fact that's not a big issue.

A Nautix carbon boom with a homemade end piece connecting

the end tubes. Using large pulleys reduce the friction and

allow more clearance between the outhaul lines and the

pulley in the clew grommet.

Click the picture to enlarge.

Another homemade end piece, this time for an old Fiberspar carbon

boom. An end piece is exposed for a lot of stress and has to be

strong anchored in the end tubes and made from strong material.

This end piece is made from an old G10 fin.

Click the picture to enlarge.

One thing that even

the newest carbon booms normally don't have is a kind of guidance, so

that the line between the outhaul clam cleats and the

tail end

pulleys

doesn't get

hooked by the (Chinook or Nautix) pulley that many of us place in the

clew grommet. Luckily this doesn't happen that often - but

when it

happens (mostly after a jibe) you're often in a hurry and are not in the

mood to use time to get the lines free. And getting the lines free is

almost impossible, unless you let the

sail go and swim out to the clew.

As said, very few

booms (if any) are prepared for outhaul line guidance, so you'll have to

fix it yourself - if you think that it's a problem.

Homemade guidance of the outhaul line to avoid it from being

hooked by the clew grommet pulley. Here placed on an Aeron

carbon boom.

Click the picture to enlarge.

Another simple way for outhaul line guidance. As can be seen the lines

are guided by a couple of outhaul clam cleats where the "teeth" have

been removed to allow the lines to run freely. Here placed on a

Maui Sails carbon boom.

Click the picture to enlarge.

How does the Platinum

boom meet this demand?

The pulley system in

the tail end of the Platinum 190-250 cm boom is very ingenious

and allows looping the rope through the clew grommet (but not if using a

Chinook or Nautix pulley). There's

a slight asymmetry in the way the outhaul line connects to the pulley in

the clew grommet (if you use this device), but more important is that

the tail end pulleys run

with very little resistance. It's pretty effortless to operate

the outhaul trim.

Along with most

(all?) other boom manufactures North hasn't prepared the Platinum boom

for any outhaul line guidance.

One of the reasons for using pulleys in the grommet is that you

can loop the outhaul line around the pulley without having to

dismantle the line and thread it through an eyelet every time you

rig the sail.

However, the Platinum boom in fact allows looping the outhaul

line through an eyelet without dismantling/threading the outhaul

line.

Click the picture to enlarge.

Nevertheless I've chosen to use pulleys in the grommets and place

some outhaul line guidance on the tail end of the Platinum

190-250 cm boom, mostly because

of presumably lower friction.

Click the picture to enlarge.

Update September 2015.

Don't know what I've been thinking, not using the very special loop-loop-go outhaul system of the Platinum boom! A couple of weeks ago I finally tried it on the water, and it works extremely well.

One thing is that it's a very quick loop-loop-go system. Another thing is that the system works with very little friction. But the best thing is that you never have to use the Nautix or Chinook pulleys in the grommets any more. And consequently that you never more risk the very annoying outhaul line catching incidents that are associated with the mentioned pulleys.

Click the picture to watch the video.

10. The extension system must be smart, strong and tight

.

The bigger carbon

booms normally expand the diameter of the tubes back towards the tail

end, so that the oversized diameter tail end can run

inside the tubes.

This way the booms are stiffened up - but it follows that you'll have to

cork the tubes a long way up the tubes to leave room for the tail end.

When you extend such a boom, there's a possibility that water can be

trapped in the tubes.

This classic shape

also creates restrictions on how long tail ends the boom can be fitted

with. Or at least, with extra long tail ends the boom cannot be fully

collapsed, as the tail end either hits the corks or the walls of the

conic tubes.

How does the Platinum

boom meet this demand?

One of the key

features of the Platinum 190-250 cm boom is that the tail end runs

outside the tubes. This way it's possible to cork the tubes at the

extreme

ends,

so that no water can be trapped inside the tubes. And as discussed

earlier ("5."),

with the special Platinum tail end

system

no water can be trapped inside the tail because of this

being open and drainable.

The unique "outside.tail" of the Platinum 190-250 cm boom

allows corking at the extreme ends of the tubes.

Click the picture to enlarge.

The Platinum

extension system also allows more freedom in the sizing of the tail

ends. North has made use of this possibility to offer different sized

tail ends to the racing boom.

I can't tell about

the durability of the extension lock system of the Platinum boom. But

for the time being I can say, that the lock mechanism

seems very

reassuring in perceived solidity and finish.

11.

The grip must be of a

reasonable quality and must be bonded in a durable way.

Perhaps surprising,

but a lots of (the very expensive) carbon booms are fitted with extremely

vulnerable grip - or the grip is bonded to the booms with lousy glue. How

complicated can it be - a very high

priced pieced of gear of course has

to be fitted with quality grip, using quality glue.

The worst booms I've

come across in this respect are Maui Sails booms

and Neil Pryde

X9 booms (Neil Pryde in fact found it necessary to

launch a re-gripping program!).

Also pretty bad were some

(not all)

Fiberspar booms, while I've generally had

no

problems in this respect with Nautix and Aeron booms.

My Maui Sails carbon booms all look like this - in spite of

numerous attempts to fix the problem.

Click the picture to enlarge.

This very old and well used Nautix carbon boom (with a Fiberspar front

and a Streamlined head) shows no sign of grip delamination because

of poor bonding. And the grip itself seems to be of considerably higher

density than for instance the Maui Sails booms.

P. s.: Please notice the line that are fixed on the tubes and runs

through the boom head ahead of the mast. This

precaution ensures that you can in fact sail ashore,

should the boom front loosen or break.

Click the picture to enlarge.

How does the Platinum

boom meet this demand?

This isn't a long

term test, but from the rather restricted use of my Platinum boom so

far, I am confident as to the quality of the grip. The grip seem to be

of fairly high density, and I've found absolutely no evidence

that the grip will peel off.

12.

A place to fasten the

uphaul line, please.

A place to fasten the

uphaul line ought to be too self-evident to mention. But nevertheless

you repeatedly meet obstacles in the discipline to tie the uphaul line

to the boom head or the boom front. Often you have to find a very thin

line and thread it through a long and extremely narrow hole - and then

tie it to the uphaul line (Maui Sails and Fiberspar heads). Other times

you're left to tie it directly to the boom front, so that it restricts

the clamp on mechanism (Streamlined head). And probably numerous other

"solutions".

Of course, it's not

rocket science

for us

to find a way to tie your uphaul line to the boom. But

why do we have to bother?

To fasten the uphaul rope to this

Fiberspar boom head, you'll have

to find a very small diameter line,

thread it through a tiny hole, and

tie it to the uphaul rope.

Click the picture to enlarge.

A Maui Sails boom head with the

same unnecessary complex procedure

for securing the uphaul rope.

Click the picture to enlarge.

This Aeron boom is perhaps a little

better in this respect than the

Fiberspar and Maui Sails way -

but not much.

Click the picture to enlarge.

At this Streamlined boom head/

front you're allowed to tie the

uphaul rope directly to the front

without using a small diameter

line. But now the uphaul rope

interfere with the clamp lever!

Click the picture to enlarge.

How does the Platinum

boom meet this demand?

The Platinum boom

head simply present for you an eye big enough for you to thread the

uphaul line directly. It's placed where it belongs - just beneath the

clamp mechanism.

The North Platinum iFront 2.0 (and iFront 1.0) way to fasten the

uphaul rope directly in the boom head. A BIG eyelet under the

clamp lever. Simple and effective!

Click the picture to enlarge.

13. The boom head must either be hinged to the boom front - or have a little play that allows different

angles relative to the mast

.

I think all modern

booms allow different angles to the mast. The "Nautix way" to obtain

this is by letting the boom head be suspended

from the boom front by means

of a elastic connection. This way, the boom can pivot up and down, but

it always seek back to a kind of equilibrium.

The other and usual

way is to hinge the boom head to the boom front. The boom has no

equilibrium but stays in the position it's left. How easy

and smooth the hinging

works depends

on

how much you tighten a couple of bolts. Usually, to obtain more friction

(and to take care of the boom front?) some rubber/plastic shim(s)

are placed between the head and front.

The Nautix boom head is connected to the boom front with some

torsion bars. The boom can change angle relative to the mast, but

it always seek an angle of 90 degrees when not under load.

Click the picture to enlarge.

The normal way for suspending the head in the front by means of a

hinging mechanism. The Maui Sails system (upper picture) implies

shims between head and front to have some friction. The North

Platinum system (lower picture) have no shims, but the textured

surface of the front seems to compensate for the apparent lack

of friction.

Click the picture to enlarge.

How does the Platinum

boom meet this demand?

The Platinum boom

belongs to the hinged type of booms, but contrary to most others it

hasn't got some shim material to create a little more friction. However,

as the carbon material in the boom front is

slightly

texturized, too little

friction doesn't seem to be a problem. If there'll be some long term

grinding effect on the boom head

because of the lack of shims,

I don't know.

14. Preferable the boom front must have a "standard diameter" that allows boom heads from other brands

to fit

.

The Platinum 190-250

cm boom front has a diameter of approx.

35

millimeters. That's almost in

line with

Aeron booms

and (probably) others - but it's a lot narrower than the fronts of

for instance Maui Sails

and

Fiberspar booms

(approx. 40 millimeters).

How does the Platinum

boom meet this demand?

This certainly isn't

a big issue, but from experience I know that from time to time it's

convenient to be able to switch boom heads from brand to brand. And in

this respect it's reassuring to know that

in an emergency situation

you can take a take a

boom head from other brands and place it on a Platinum boom

- and vice versa.

Verdict.

To summarize according to the listed criteria and findings:

1. Made from carbon? ....................................................... Yes (a very high quality carbon).

2. Monocoque construction? ............................................. Yes.

3. No boom sliding. .......................................................... Check (iFront 1.0 & iFront 2.0).

4. Clamp mechanism friendly to the mast? ....................... Yes (at least iFront 2.0).

5. No water in the boom. .................................................. Check (very convincingly).

6. Relatively narrow between the tubes. ........................... Yes.

7. Classic shape. ............................................................... Yes.

8. Max. stiffness. .............................................................. Check (very stiff).

9. Prepared for outhaul trim. ............................................ Check (prepared for loop-loop-go)

10. Smart, strong and tight extension system. .................. Yes (paramount!).

11. Quality grip. ................................................................ Check.

12. A place for fastening the uphaul line. .......................... Check (very userfriendly).

13. Pivoting boom head. ................................................... OK.

14. Front diameter allows boom head interchangeability. . OK.

This is no durable

test, but in this early stage of the life of my Platinum boom it has

indeed proven a very, very promising performance. It's pretty seldom

I've taken some new windsurf gear into

possession without finding any major flaws. But that's the case with

this

boom.

The North Platinum

boom certainly doesn't come cheap

(in my country). But with the current experience I'll

rather save up money to be able to buy a North Platinum boom tomorrow

than buy a cheaper carbon boom from any other brand today.