|

Click the pictures for enlargements.

The current quiver that's basis for most of this valuation.

Click the pictures for enlargements.

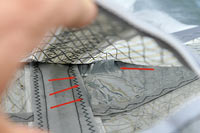

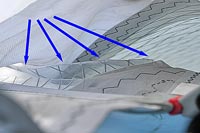

Above: 5 examples from the never ending story: pictures of cracked luffs in (from the top) an RS4 7.2, an RS5 7,8, an RS Racing 8.4 (red arrows), the same sail 2 weeks later with a similar damage at a lower batten (blue arrows).

Unfortunately the Neil Pryde luff cracking problems aren't restricted to their Racing series. Above you see examples of cracked luffs from a RS Slalom 7.2 and a V8 9.8.

One of the bad signs to look after: Winkles diagonally in the mast sleeve indicate that the luff has cracked, letting the mast sleeve take too much of the load.

A little selection of broken batten tips - probably a result of point- loading of the ends caused by the rigid square tubes in the luff.

The lowest batten of the newer RSS's are made from small diameter tubes only. Of course, the lowest batten shall always be pretty exposed, and perhaps it's a bit optimistic (durability wise) to place a pretty weak batten here.

It's not often that the top batten breaks - but IF this happens it's NOT exactly quick or simple to replace.

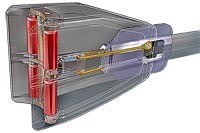

The very complicate d and vulnerable RS Racing camber system. It's not quite easy to figure out the way of function, but some of the declared easy rotation quality probably comes from some elasticity and flexibility in the different parts.

A small harvest of broken cambers and batten end cartridges.

When replacing a broken camber be aware of tying the strings fixating the camber perpendicular to the mast very precisely. In fact if you try to imitate the fixation method of the manufacturer, you'll have to sew the strings ...

If you don't want a lot of breakages in the batten-camber system it's best NOT to follow the video rigging instruction, telling you to tension away all the wrinkles along the batten pockets in the lower part of the sail.

Sometimes the cambers come with a sloppy string fixation, causing the cambers to tilt on the mast. Here a tilted camber has almost destroyed a X6 mast, and it's been necessary to beef it up with some carbon weave.

The arrow show the place on the batten tensioner that is exposed to break if you operate it on a downhauled sail.

The top strap on a RS Racing 9.8 has just exploded.

Some characteristic places for wear and tear. The RS Racings are probably not worse in this respect than most other race sails.

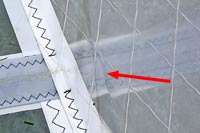

A RS Racing 9.0 with a X6 490 cm mast has just been downhauled, and the zippers now have to be operated. It's pretty obvious that the zipper just below the boom has a lot of stress and shall be tricky to close. When forcing the zipper to close, the stitching holes are drawn oval - a clear sign of the load. This time the zipper didn't brake - but what about the next time?

A couple of incidents with newer X9 masts (picture for illustration use only!) that couldn't be separated after sailing sessions are described here. Don't know how symptomatic these incidents are ...?

Even with the X6 masts you don't quite avoid breakages. Here a X6 550 has broken in a RS Racing 10.7, causing the sleeve to split wide open. Apart from the loss of a mast and damages on the sail a mast breakage often imply a long paddling journey back to the shore - with a great risk of loosing parts and/or damaging the board with all the bits and pieces you have to keep together on the board. Using X9 masts you'll have plenty of chances to practice the paddling technique ...

Click the pictures for enlargements.

|

Some experiences with the Neil Pryde RS Racing sails.

Introduction.

I must confess that this isn't entirely a love story, and of course you shall take in consideration that it isn't a super-human valuation. When you've had so many (expensive and time consuming) problems with the quality of the RS sails from the last 4 years it might be a problem to be absolutely objective. I love the sailing quality and performance of the sails, but in fact that just ad to the frustrations by having to stay ashore because of the very frequent breakdowns of the sails. The basis for the valuation is primarily my own experiences, but the experiences of my sailing buddies and the windsurf community at my place also count to the greater picture. And of course you can't be quite immune to the general picture you get when reading about the RS Racing in the various windsurfing forums.

General performance.

The first thing you notice with the rigged sail is probably the very wide sleeve (the widest of all race sails?), the very deep draft, and the very sudden start of the loose leech, beginning from the 2. batten above the boom. From the mentioned batten and diagonally up towards the sleeve the panels very suddenly "falls away" in a very Neil Pryde typical way.

In line with the appearance the Neil Pryde Racing is generally a very powerful sail that plane early and very easily keep its plane through the lulls. If you've got the power (and weight) to convert the pull to board speed the sail's also very good in overpowered conditions, as the draft doesn't move back much in the gusts. However, as the sail try to convert all small and big gusts to pull without much dampening of the power it might also feel a little demanding - especially if you sail a kind of boards that feel as they lie high and free on the water. For instance, I usually use my RS Racing 8.4 with a Tabou Manta 74, and in overpowered conditions it both feels very quick and feels very nervous - threatening with jumping out of the water. If you sail this kind of "nervous" slalom board with your RS Racing, you'll probably use it with a pretty small fin to have control.

As said the sleeve is very wide, and as there seem to be a kind of scarcity in draining canals, it can be a hell of a struggle to get the sail out of the water (for instance after a crash with your formula gear). In the winter time with gloves it's almost impossible to uphaul the sail if it has had the time to fill the sleeve with water.

Much have been said about the new RS Racing cambers (the Ultracams, apparently the only difference from the RS6(?)) and their ability to rotate. In short - I've never had the pleasure to rotate the Ultracams in my sails without having to kick them or to pump fiercely. It might be a question about having the right mast (see below) - but for now I'm not impressed by the rotation ability of the Ultracams at all.

So to conclude - the RS Racings are very fast sails that probably fit stronger and heavier sailors better than lighter sailors, that probably fit stable and flat sailing boards (for instance Starboard Isonics?) better than "free sailing boards", and that is better in straight line sailing than in sailing with a lot of jibing or tacking.

The luff.

Just for clarity: By "the luff" I mean the part of the sail from the top strap to downhaul strap that is hidden in the sleeve - and that takes the major part of the downhaul load/stress. The RS4 from 2004 was a real revolution among the race sails. Some of the characteristics were a much wider sleeve, new and lighter sleeve material and more luff curve. The sail was widely renown for its performance, but unfortunately it was also known for being prone to material failure. All of the RS4s got tears high up in the sleeve, and (more serious) all of the RS4s sooner or later (unfortunately most sooner) cracked in the luff inside the sleeve. If you didn't notice the cracked luff very quickly (a sign was wrinkles diagonally in the sleeve and still less resistance when applying downhaul) the sail most often suddenly split up through the panels, turning the sail to pure garbage.

It was a widespread theory that the reason for this was the much more luff curve relative to the RS1, RS2 and RS3, and the theory was supported by the fact that the NP race mast (the X9) was at least as prone to break as the luff was to crack or split up through the panels.

Now, what has Neil Pryde done to the RS5, the RS6 and the RS Racing to solve this luff cracking problem. In fact, apparently very, very little! That is, the RS5 was as disastrous in this respect as the RS4, but the RS6 and the RS Racing "need" some more time on the water before it happens. And unfortunately it's the same story with the RS Slalom and the V8s from the last 3-4 years. What to do when you observe one of the signs of a cracked luff? Very quickly de-rig the sail, take out all the battens and the camber closest to the damaged area and bring the sail to your local sail repair loft. The repair man then shall open the sleeve at the damaged place and strengthen the cracked luff with some new material. Hopefully he has made this operation before, or there's a great risk that he shall underestimate the downhaul force the luff is exposed to. The repair price for a professional job normally lie between 100$ and 300$, but if the cracks in the luff aren't noticed in due time it's most often not worth repairing the sail. To complete the picture, in this country (Denmark) the average time for getting a Neil Pryde authorized repair is at least 5-6 weeks (autumn 2008).

The luff material typically cracks around the first batten/camber above the boom, so this is the place you'll have to inspect first, if you suspect this systemic failure in the Pryde race sails.

It's a little time consuming - but it is in fact possible to do a simple repair (without a sewing machine) of the cracked luff of your RS Racing/Slalom (or other cambered Neil Pryde) sails by yourself. Further details here.

The camber inducers and battens.

Breakage of the tip of the battens.

The high quality main battens are made from short rod battens next to the cambers, superseded by small diameter tubes that are finally superseded by larger diameter tubes next to the batten tensioners.

It seem to be a common failure these days that the tips of the Neil Pryde race sail battens break close to the cambers. Batten tips from race sails from other brands can have a tendency to break too (for instance Maui Sails TR series), but apparently not at the rate of the Neil Pryde sails. The reason probably lies in the (white) hard square plastic tubes (placed in the luff) that hold the battens ends in place just before they enter the cambers and cartridges - and that (opposed to sails from most other brands) don't allow the batten tips to spread their flexing over the entire batten ends. It's probably this point load of the batten tips - inherited in the "Ultracam" design - that results in this frequent arisen problem ...

Mostly the tip breaks when you de-rig the sail and forget to actively push off the cambers from the mast (never let the cambers pop off by themselves by just loosen the downhaul tension!). It's almost entirely the two lower battens that break during de-rigging. But from time to time the tips also break from other more diffuse or perhaps not explainable reasons, and when inspecting the the batten ends you'll often observe that the ends show small signs of de-lamination under the shrink material.

When a tip breaks in an older RS sails it's not always easy to push back the broken tip out of the batten sleeve. However, pushing the tip back from outside the batten sleeve by means of a relative smooth piece of wood (i. e. a hammer shaft) most often do the job. For a start it might be necessary to drill a little hole in the plastic ends containing the batten tip and push it a little back before you can start pushing from the outside. With the newer RS Racings (and the RS Slaloms) this first step is much easier, as the batten tips are "floating" in plastic containers held in place by strings.

When replacing the rod part of the batten by yourself, you can fit almost all not original rod battens to do the job - but it seems that the blue rod parts from older Neil Pryde sails are just a little bit stronger than other rod parts. If you replace the rod part of the batten by yourself you'll have to ... - remove the shrink plastics around the transition between the rod and the small diameter tube - grind or cut away the glass weave around the transition - push or tap out the (most often) 2 small metal sprigs (nails) - heat the place (by means of a heat gun) to soften the (epoxy) glue - pull out the rod from the small diameter tube - glue the new rod in the small diameter tube by means of epoxy resin - laminate a little glass or carbon weave around the transition.

Breakage of small diameter tubes.

Neil Pryde seems to have so much confidence in the strength of the small diameter tubes that they have started to use it as the only tube in the lowest batten of the RS series. These small diametre tubes are perhaps a benifit performance wise - but they're generally not strong enough for the job, and we've seen a lot of breakages so far at my place. Because of the repeatedly breakages some local sailors have simply substituted the originally small-tube-only lower batten with a large diameter batten from older Neil Pryde race sails. Of course the prize to pay is a stiffer and a perhaps not so ideal profile low down the sail, but at least this solution gives you a fair chance to spend some more time on the water ...

The top batten is also made by a small diameter tube, but as this batten's not nearly as exposed as the lowest batten, it seldom breaks. But IF it breaks, the replacement proces' not especially user friendly (see further details here).

The cambers.

The cambers of the RS Racing and the RS Slalom sails are the most complicated camber system at all so far. Much have been said about the way they function (for instance something like "the pressure on the cambers is eased when rotating, making the rotation effortless"). It's really not quite easy to figure out how the cambers should do that, and it's obvious that a part of the declared easy rotation quality come from the elasticity and friction of the strings and cambers. If you for instance follow the advice of some team-riders and wrap some Kevlar tape around the cambers (to avoid breakage, see later), the cambers immediately rotate a lot worse, indicating that some of the normal rotation quality come from the cambers being a little soft and flexible.

Ok, to start with the rotation quality, I've not observed that the new "Ultracams" rotate better or worse than other much more "primitive" cambers. I shall confess that I haven't got the money to buy new X9 masts in the rate they break, so I've primarily rigged my RS racing with X6, X7 and North masts. No matter how I rig the sails the cambers never just rotate - they have to be kicked, pushed or to be exposed to fierce pumping (not easy in low winds). However, contrary to other cambers, that tend to pop back to the starting point if you don't rotate them in the first place, you can pump the Ultracams little by little, so they end on the right side of the sail.

Another thing is that if you look at the instruction video from the Neil Pryde RS Racing site Micah Buzianis clearly tell you to tension the battens so that all wrinkles between the panels and the sleeve disappear. But if you do so, the cambers don't rotate at all (at least on the X6 masts), and both the cambers and the little plastic cartridge keeping the batten tips in place tend to break quickly.

And talking about breakage - the cambers break frequently, and so do the cartridges for the batten tips. If the sail start wrinkling along the battens and some of the profile of the sail disappear, then you surely have a breakage problem. Some spare cartridges come with the new sail, but you'll have to buy replacement for the broken cambers (in Denmark for a price of some 60 $).

Some other thing to be observant on is the strings that keep the cambers in place vertically. Sometimes the strings are not fitted properly from the factory, allowing the cambers to tilt on the mast and cut deep grooves around the mast. If you don't discover the grooves caused by slack strings pretty soon, it might be too late for saving the mast!

Batten tensioners.

From one point of view the batten tensioners are pretty clever. Partly because they're easy to operate (no key needed) and partly because they're making an almost neutral pressure on the battens - that is they (almost) don't pre-bend the battens to one side as you experience from the kind of (larger) tensioners with a more angled pressure). However, if you try to operate the Pryde tensioners while the sail is downhauled there's a bad risk that the plastic "leafs" shall break. A "leaf" is pretty awkward to replace, and you almost certainly need to visit your sail repair man.

This kind of vulnerability of batten tensioners means that adjusting the batten tension is a kind of trial and error: Adjust the tensioners - downhaul the sail (and popping the cambers on) - enough? No! - releasing the downhaul (popping the cambers off) - adjust the tensioner - downhaul the sail (popping the cambers on) - enough? ... and so on.

The downhaul strap and the top strap.

I'm not sure if the Neil Pryde race sails are more prone to split up in the webbing or in the stitches than other race sails - but they pretty often do. You should think that not much ingenuity and craftsmanship are needed to minimize this problem (some strong webbing, strong stitching and proper placement should do the job), but apparently its a little more complicated than you should think(?). See video clip here.

The sleeve.

Again I'm not sure if the Neil Pryde race sails are better or worse than other race sails in this respect. But nevertheless the sleeve (especially around the upper cambers, opposite to the zippers) is prone to get worn out. The damage normally doesn't effects the performance of the sail, but if the sleeve is badly worn out it's easy to glue/stitch on a patch (entrance through the zippers) to the area without having to open the sleeve. Another minor week point is the elastic boom cut-out material (with a double operating zipper) that might get worn out.

The zippers in the sleeve.

Generally the zippers are of very good quality, but it is possible to over stress them. The stressing of the zippers very often happens if you use the sail with a non-X9 mast that's softer in the bottom area than intended (almost all non-X9 masts seem to be too soft for the RS Racing in the bottom area).

The problem probably occur because the more (relatively) softness in the bottom area of non-X9 masts try to make more bend curve in the lower part of the sail than the sail is intended to, stretching the sleeve to almost drumhead proportions.

The problem seem to be most obvious with the zipper just below the boom, and unfortunately the phenomenon is also easily observed with the X6 masts that a lot of guys have to use (because of the famous vulnerability of the X9 masts). This apparent (minor?) lack of compatibility between the bend curves of the X6 and the X9 masts is a little strange, because measuring the X6 masts they fit pretty fine to the Neil Pryde bend curve label ("Constant Flex", that is a bend curve around 15 (see database here)). This should mean that the newer X9 ("Ultra") masts (that I haven't had the opportunity to measure lately - for good reasons, as simply non of my sailing mates dare to buy a new X9 mast!) are presumably even more Flex Top than the X6 masts.

The clew.

The clew has two eyelets, and it seem to be most common to use the lowest one and in this way weigh control over a (marginal) tighter leech. The normal place for eyelets has been cut away, thereby placing the eyelets around 10 cm closer to the mast than comparable sails. Neil Pryde think this allow a looser leech (more twist) and a smaller and more compact boom compared to an ordinary eyelet placement.

This might be so, but the price also might be that it's not as easy to tighten up the leech and control the power of the sail by means of a variable outhaul system as in other sails. Fortunately the RS Racings are very draft stabile sails, but once powered to the max (compared to the sailor weight and ability) you haven't got the usual very effective mean of pulling the outhaul lines to lessen the draft depth and shifting the draft more forward in the sail. Apparently one reason for this is the eyelets not being placed closer to the (imaginary) leech - another reason seems to be the eyelets being placed under the 2nd batten from the bottom (the so called cross batten, coming from under the boom on the mast side and and ending over the boom (eyelets) on the leech side). In a recent test in the German mag. "surf" (No. 07/2008) this observation is implied by the fact that the only tested tested that hasn't got either cross batten or cut away eyelets or both is the Gaastra Vapor - and exactly this sail is praised to be the most outhaul trim sensible sail in the line up.

The masts.

The recommended mast - the X9 mast, now in the "Ultra" edition - is (or at least has been) a true scandal. If you're a non-sponsored sailor you'll have to be very rich to keep buying new X9 masts in the rate they brake (restricted warranty (if you're lucky) at my place). And furthermore, it's far from cheap to get your race sail repaired, if the X9 mast breaks inside the sleeve (it normally breaks in the area above the boom and around 1st batten/camber above the boom). The reason for calling the X9 mast a scandal is (among other things) that other masts have had similar durability problems for a shorter period (for instance Gaastra Ignition masts and the early Maui Sails SRS masts), but while these brands have succeeded in beefing their masts up to an acceptable level of durability within months, Neil Pryde haven't been able to tackle their severe X9 durability problems within 4 years!

What to do then? Well, some RS Racing sailors claim they use Severne 100% race masts with great success, and some sailors say they use Gun Sails 100% race masts with equally great success. Apparently they don't break at the same rate as the X9, apparently their bend curves are only a little less Flex Top than the X9, and apparently they are made from one of the two Italian manufactures that is responsible for the majority of high end 100% race masts. For instance the Severne and Gun Sails race masts are clearly lighter and more high end products than the China made Neil Pryde X6 masts.

Talking about the X6 masts - many RS Racing sailors (including myself) at my place have opted for the X6 mast to replace the recommended X9 mast. This is certainly not an ideal choice, but given the fact that no one has come up with credible information that NOW the X9 mast finally has achieved a level of quality that correspond to the astronomic price level, the choice of the rather inexpensive China made X6 mast might be understandable. The first you notice about the X6 mast is that it's somewhat heavier than most high end 100% race masts. The larger sizes are claimed to be made from 100% carbon(!?), but still they're pretty heavy. It seems that the weight come from the wall thickness, and if so the the action-response speed have to be somewhat slower with consequence for the performance. Furthermore the X6 masts doesn't seem to have exactly the same bend curve as the X9 masts. Judged from the shape of the sleeve the X6 masts seem to be relatively softer in the bottom area/stiffer in the top area than the X9. Put in another way the X6 mast seem to a little less Flex Top (tipping around bend curve "15") than the X9 mast. That said, the X6 mast deliver very good performance inside a RS Racing sail, and in reality the only thing that hold you awake is when other (team) sailors tell you that the performance of the RS Racing is better with a X9 mast.

A parenthetical remark: At my place we've had a couple of incidents with newer X9 masts where the top and bottom sections couldn't be separated after sailing. Until I learn about similar stories I don't want to speculate, if these happenings has to do with the X9 masts per se, but here you've got a chance to valuate for yourself (and see how we succeeded in separating the sections of the X9 masts).

One last thing - X6 masts do break too, but only at an "normal" rate. When one of your X6 masts breaks it might be useful to know that the 550 cm and the 520 cm X6 mast "share" the same ferrule (that is a 520 cm bottom and a 550 cm top fit together - and vice versa). In the same way a 490 cm and a 460 cm X6 mast share the same ferrule, and a 430 cm and 400 cm X6 mast share ferrule. For instance - for the last half year or so I've been sailing my RS Racing 10.7 with a X6 mast that is put together with a 520 cm X6 bottom and a 550 cm X6 top. Of course the stiffness and the bend curve of the mast shall be a little different from either a 520 cm X6 mast with a long extension or a 550 cm X6 mast with a relatively short extension. But the fact is that the sail feels better than with the alternatives that I've tried, a 550 cm X6 mast (that broke) and a 550 cm North Platinum mast (that's a little too stiff and Constant Curve).

Conklusion.

The RS Racing sails show very good performance, but is perhaps a better sail for the powerful and heavier sailor than for lightweights. Recent tests (for instance the mentioned test in the German "surf" mag. (No. 07/2008)) indicate that the RS Racing has lost its advantage to the competitors - and that in spite of the RS Racing being made with far more technical solutions than for instance North Warp, Gaastra Vapor, Maui Sails TR4 ... etc. That is - while you a couple of years ago (perhaps) accepted the higher vulnerability of the Pryde race sails because of their better performance, you now tend to pay the same high price in terms of frequent breakdowns of especially luff, cambers and masts (if X9) - but without the earlier benefit in terms of paramount performance.

A last word.

Well, this is my story, and of course I can't be sure that other RS Racing sailors have experienced the same. At this point of a (personal) verdict of the RS Racing sails you can almost already hear the chorus: I don't agree - now I've sailed 2000 hours with my Neil Pryde RS Racings, and there's never been anything wrong with the sails. To those of you who pay your own equipment, who sail hard and fast, and who really downhaul the sails to the recommended specs I'll say: Damn, I think you've been lucky. And to those of you who are more or less sponsored by the Neil Pryde company (or aspire) - that is who are paid to promote a god reputation of the brand - I'll say: Isn't it time for you to show some solidarity with the ordinary, non-sponsored windsurfers, and tell us honestly about your experiences with the sail. Don't wait to tell us about your true experiences until you get a new sponsor agreement with a competing company (a kind of sudden frankness often witnessed).

Read the response to these words from Pieter Bijl from the Neil Pryde Design Center (NPDC).

----

Not tired of personal reviews?

Perhaps to no surprise I gave up sailing the Neil Pryde race sails. But then what? Because of a reputation of being a sail brand with very well built and durable race sails, I (and my son) switched to the Warp series from North.

Here's a link to the review: On North Warp, a personal review. 6 years with the Warps.

|